'91' SeRIES PLASMA ABATEMENT

Welcome to the next wave of abatement technology. The 91 series next generation plasma reactor is a game changer with unrivalled PFC chemical destruction removal efficiency.

Our propriety state of the art waveguide design is stable, requires no heated elements and no fuel gas. This ensures very low background emissions, most notably the considerable NOx reduction in comparison with traditional combustion burners.

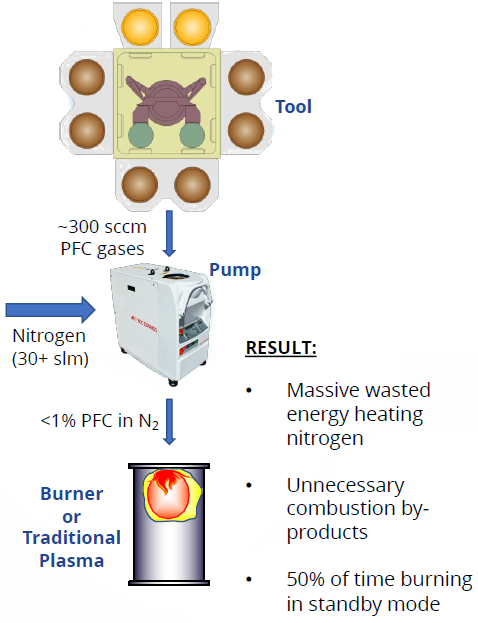

Traditional Abatement Technologies

Typical approaches treating non acid/water-soluble gases include; thermal-electric/wet, burn or burn/wet, IPC plasma/Arc plasma. All of which has there own set of obstacles and limitations:

- High cost

- Substantial energy consumption

- Requires fuel gas

- Combustion creates some GHG’s

- Relies on heat

- High running costs

- Difficult to maintain plasma stability

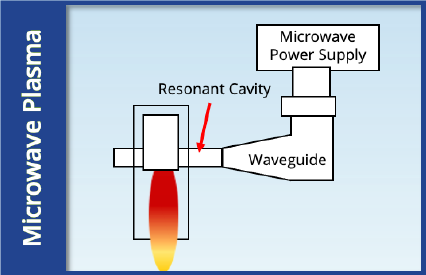

The Solution - Our New Proprietary Microwave Plasma

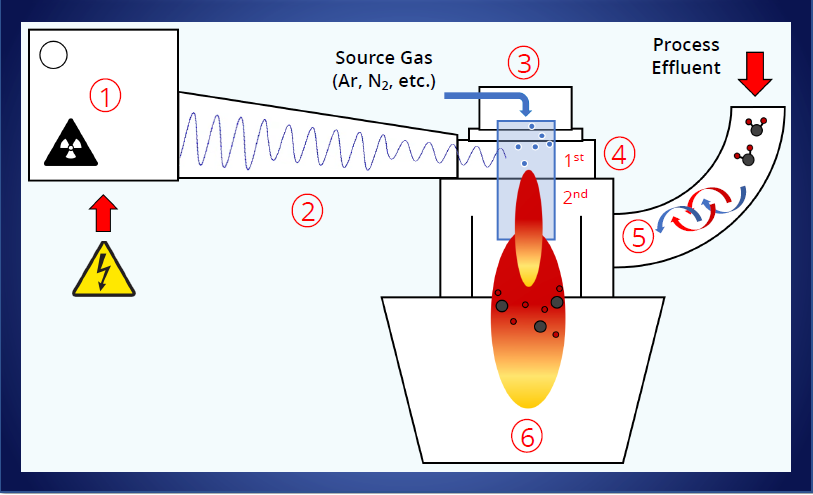

1 – Magnetron converts small amount of electrical energy into microwaves

2 – Proprietary waveguide drives microwaves to center of a quartz tube to maximize “plasmarization” process

3 – Plasma source gas (Ar, N2, etc.) enters 1st stage plasmarization zone

4 – Plasma source gas decomposed by microwave energy releasing large amounts of high kinetic energy electrons

5 – Turbulence causes effluent gases to swirl into 2nd stage of plasma reactor where the highest microwave energy resides, and target molecules are dissociated in the plasma. Reaction rate further enhanced by collisions with high kinetic energy electrons from 1st stage plasmarization zone

6 – Atoms from target molecules recombine into desired by-products (lower energy state)

Advantages

- Low energy consumption microwave plasma

- Proprietary waveguide design

- Stable

- Low-cost combustion option

- No electrical heaters and no fuel gas!

- Huge NOx reduction